Cruising with Mr. Perkins - Rebuild or Repower?

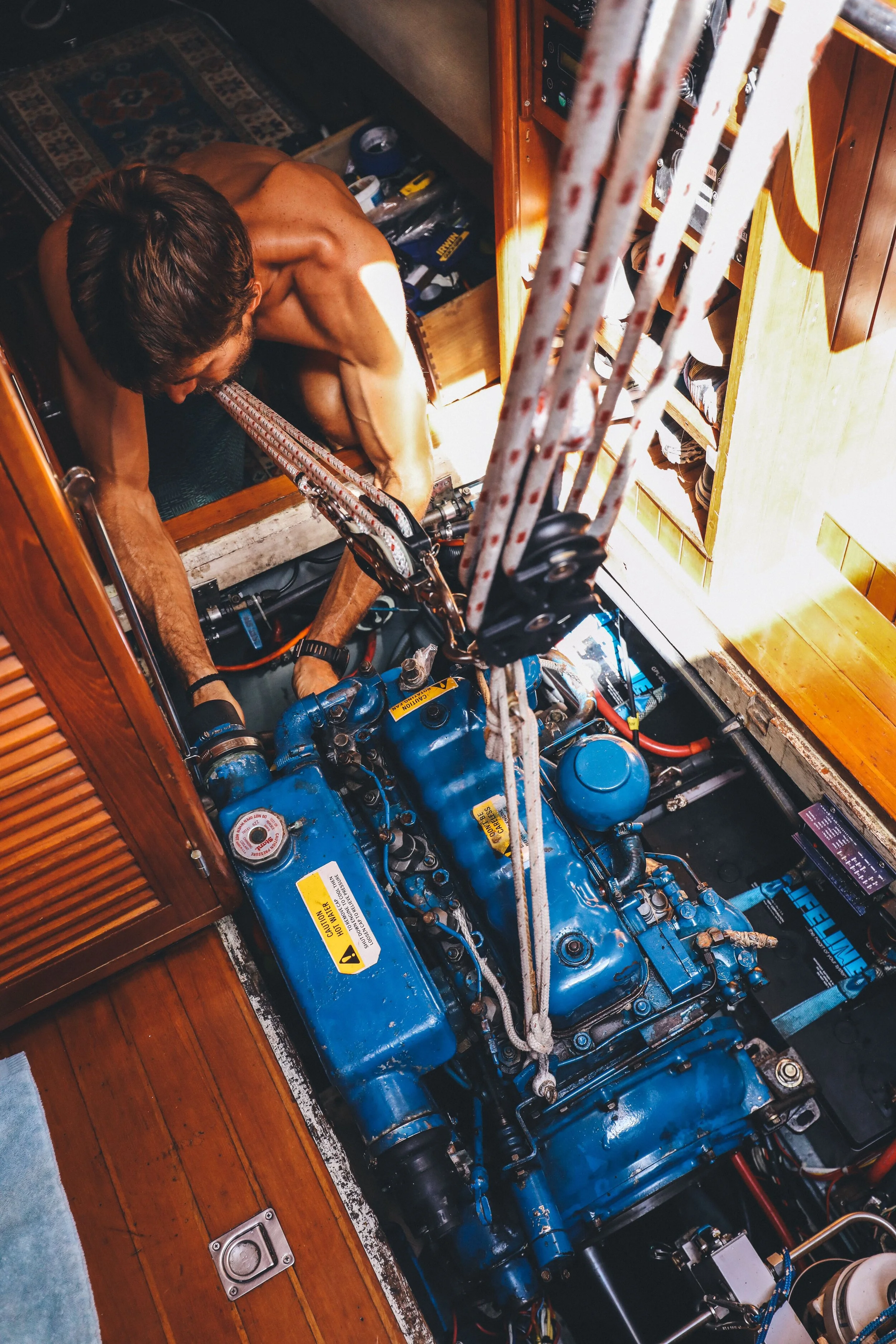

Deep in the wire and hose infested bilge of Agape, resides an iron monster, a relic from another age, pre-electronic controls and clean air acts. This big blue, British diesel is the heart of Agape. Pumping power to both the drive train and the batteries whenever we so desire, well almost whenever.

My Father was a diesel mechanic by trade and I worked all around them in the oil field, but truly the inner workings of diesel engine was a mystery to me. When we first bought Agape I did all the research I could on every different system onboard, but out of fear our engine was left overwhelmingly unknown.

As we prepared the boat for long term cruising the question of re-powering came up often. Our trusty Perkins 4-108 had always run well. In fact, when we bought the boat down in La Paz, Mexico, I motored her almost the entire 1,100nm back to Ventura. At one point I ran the old boy for 5 days straight. Other than leaking a insignificant amount of oil, we had no complaints. But it didn’t change the fact that he was still 32 years old and had well over 5,000 hours of run time.

Not knowing how the engine had been treated in the past, we decided to pull the engine, not to replace it but to send it to a local shop to give it some TLC. Pulling the engine was straight forward and fairly easy. We did this part on our own but other than that, once again, I bowed out and left the engine work to the “professionals”. We had them put in new front and rear seals, rebuild the injection pump, put in new injectors, starter, water pump, coolant pump, and dampener plate. We purchased four new motor mounts and had the mechanic clean and flush the cooling system, as well as give Mr. Perkins a “good look over”. $2,600 later Mr. Perkins was back at home in the bilge with the mechanics blessing, and we had purchased piece of mind.

For the next couple of years we enjoyed trouble free cruising with Mr. Perkins, he always behaved and never complained. That was until, the now 35 year old work horse decided he once again wanted a little attention. Only this time we were up a remote river system in Western Panama. When I checked the oil level one morning (which I am religious about) I was shocked and horrified to find not the usual viscous Delo oil clinging to the end of the dipstick, but an almost clear, watery substance that smelled a lot like diesel. Our sump was full of diesel! Rachel and I spent the next few hours trying to diagnose the issue, we poured over workshop manuals and Perkins troubleshooting books that we had on board since we didn’t have cell or internet service.

The most likely culprit and the easiest to remedy, was the lift pump. A mechanism that helps “lift” the fuel from the tanks and supplys it to the injection pump, luckily we had a spare on board. It was a fairly easy swap of two fuel lines and four bolts, and it only took about an hour to change. After swapping out the old lift pump it seemed that our problem had been fixed, but from this point on it seemed like we had developed quite a significant oil leak, up to a quart every twenty hours. With only a month or two left in our cruising season, we decided to wait to deal with the oil leak until we got back into a marina to decommission the boat for the off-season, when we’d have time to really think about what we wanted to do.

Over our off-season Rachel and I had several long discussions about re-powering vs. rebuilding the engine, and the pros and cons of each decision. In the end, Rachel left it up to me and said she’d trust whichever decision I would end up making. At the time I was very much in favor of replacing our old Perkins with a new, shiny red Beta Marine diesel. Essentially it’s the same engine, just modernized ever so slightly, but with a $20K+ project price tag I had some serious hesitations. After many hours of research, prayer and head scratching, we decided to keep Mr. Perkins, hoping to squeeze at least two more good years out of him.

This decision came with its own set of hurdles. We knew the engine was leaking oil and I was pretty sure that somehow we were still making oil (leaking diesel into the crankcase, also worsening the oil leak), but we had no real way of knowing what other ailments might be troubling Mr. Perkins. When we arrived back on board Agape we were armed with more knowledge, gasket kits, a couple of great pdfs and most importantly a new found desire to demystify our engine.

Step one was to pull the engine out. Once again we used the boom and compression post to lift the engine from its dark hiding place, and for the second time in so many years, Mr. Perkins was exposed to the sun light once more.

We spent the next few days replacing all the seals, put on another new lift pump, and even put on a fresh coat of paint (Ford blue instead of Perkins, but don’t tell anyone). Mr. Perkins was looking good and he ready for action!!! We had the engine out, cleaned, torn apart and put back together and into the boat all within five days!!! Pretty good time for a cruiser I’d say.

Before Mr. Perkins paint job.

After!

After reinstalling our brand-new looking, 35 year old Perkins it took another two days to re-align and bleed the engine, but when he fired up it was amazing. It was the best, near defying noise I have ever heard!

After all this work you would expect it to be happy cruising again, and for about a week it was. But, as fate, luck, karma or the diesel Gods would have it, this was not meant to be. About a week later when I checked the oil, I once again found the sump full of diesel. This time we were at Isla Contadora, in the Las Perlas Islands of Pacific Panama. We decided that it had to be the fuel injection pump at fault, leaking diesel into the system. The trouble was we could not fix the pump at anchor and we were 50 miles from mainland and Panama City. Luckily, Rachel was able to hitch a ride back to the city on a friends boat. She was up at 4am the following morning and sailed the 10 hours back to Panama City. She spent the following day scouring the city in search of a replacement pump or a rebuilt kit, but had no luck. She found a shop that said they could repair it, but they’d have to order and wait for a rebuilt kit to arrive from England, which could take up to a month. Time we didn’t have as we were hoping to begin our Pacific crossing within the next two weeks.

Luckily Rachel is a professional problem solver and she got creative, after some quick research she found the cheapest and quickest solution would be to book the next flight out to Virginia where she would then rent a car and drive four hours out into the rural country side to visit Trans Atlantic Diesel. There she’d be able to swap out our old pump for a new one, as well as purchase a new set of injectors to have on board just incase.

Three days later my rockstar of a wife was back on the boat with a new pump in hand!!!! By the next morning we had old Perky up and purring happily. Almost three hundred hours later he is still running great, and we only lose a couple of drops of oil in between changes.

So the big question, “Should we have re-powered?”. Did we make a mistake by trying to squeeze another couple hundred hours or even years of life out of this tired old motor? Well, we only have our opinion to go off of and everyone’s will differ, but we feel like the work we put in and the relatively small amount of money we spent was worth it. As of now, I think we made the right choice.

Here is my math; every dollar we have spent on this motor, including Rachel’s expenses flying back to the States, a rental car, food, hostel, parts, seals, spares, and all engine related stuff has cost us just under $4,500, a quarter of the cost of a new engine. That’s a savings of fifteen thousand dollars, which is about six months cruising budget for us!!! Not only did we save money, but we gained knowledge and confidence in our own abilities by doing the work ourselves. We know way more about how our engine works, and how to fix it if something does go wrong, which to me is extremely valuable.

Helping Halcyon get their brand new Beta Marina engine in the boat.

Also, while we were in the marina doing our work on Mr. Perkins, no less than five much newer boats, with much, much newer engines all found themselves “dock locked” with engine issues. The difference was that our late 1950’s era diesel is simple, and parts for it can be found just about everywhere. We were able to pull, repair, paint, reinstall and swap a pump by ourselves in less than a week ( and half that time was to allow for the paint to dry). Several other boats spent weeks and even months waiting for parts and/or mechanics to fix their modern, electronically controlled, highly specialized “marine” engines. All this to say, I am beyond happy to still be cruising with Mr. Perkins. He has been around the blue ball once already and he continues to show us the way!

A couple of tips for engine work:

Download and print the shop manual and parts book for your engine and have it easily accessible. I like the parts list book for our engine as it has every part and reference number, as well as great exploded views of each.

WD-40 / PB Blaster is your friend!!! Spray the nuts, bolts and surrounding area with this stuff the day before you want to start your project. It will not only help loosen the frozen nuts and bolts, but clean off some of the dirt and grim.

Lifting an engine is dangerous!!! Never stand underneath it or put any part of your body under the load. Watch for pinch points. Make sure the lines and blocks you are using are rated for the load. Play out the whole lift in your head, and do it slowly. Use extra blocks and lines to make positioning the load easier, if you try and muscle it, you will hurt yourself, the boat, or the engine.

Work in stages. Break up big projects into smaller tasks that are easier to complete. Also, clean up inbetween each task. A clean work space often produces a cleaner result!

Take pictures, notes and label everything. It’s amazing how many little nuts and bolts will come off an engine, and many are specific threads and lengths that might be hard to replace if lost or stripped. I’m a fan of removing them and immediately spraying them down with WD-40 to clean and protect them, then put them in labeled baggies until they are need again.

And remember to try and have fun!! You are doing something that most people are too afraid to do!